Your new hire accepted the offer two weeks ago. Yet when they walk in on day one, there’s no system login, desk setup, or clarity on what’s next. HR is scrambling for approvals, IT didn’t get the memo, and the manager? They’re looped at the last minute. Sound familiar?

This is not just a case of poor coordination but a process problem. Chances are, it’s affecting multiple workflows across your organization. And the worst part? These roadblocks are often invisible.

Value Stream Mapping (VSM) helps you visualize your workflows so you can identify what and where these roadblocks are. It is used by forward-thinking HR teams to decode messy workflows and design smarter, faster systems.

In this article, we’ll break down the definition of Value Stream Mapping and explore how it can improve your Human Resource Management System (HRMS) workflows.

What is Value Stream Mapping (VSM)?

Value Stream Mapping (VSM) is a visual tool for analyzing every step involved in delivering a product or service across systems, teams, and tools. It shows you how work moves, where it slows down, and what value each step adds (or doesn’t).

In Lean Management terms, it represents all the actions required to move from a request to delivery.

In HR, a candidate might go from offer to onboarding or payroll being processed on time. However, manual input, disconnected systems, or unclear responsibilities create hidden inefficiencies in your systems.

VSM gives you the visibility you need to clean up this process clutter, remove hidden delays, and make smarter use of the systems you already have in place.

Importance of Value Stream Mapping in lean management

Lean management was created to deliver maximum value with minimal waste. From an HR perspective, waste could look like redundant data entry, repeated follow-ups, misaligned systems, and delayed approvals. These aren’t always visible in dashboards or reports, but they show up in employee frustration, missed deadlines, and inconsistent experiences.

Instead of viewing tasks in isolation, VSM allows you to map the entire journey, from onboarding to performance review. Now, you can ask smarter questions:

- Where is work waiting?

- Which steps add no real value?

- How much time is spent on coordination vs. execution?

- Are manual steps still necessary, or can they be automated through the HRMS?

For example, mapping a recruitment process might reveal that approvals take longer than sourcing or that the same data is entered in three different systems. With that clarity, you can simplify workflows, automate where possible, and track performance around how value is truly delivered.

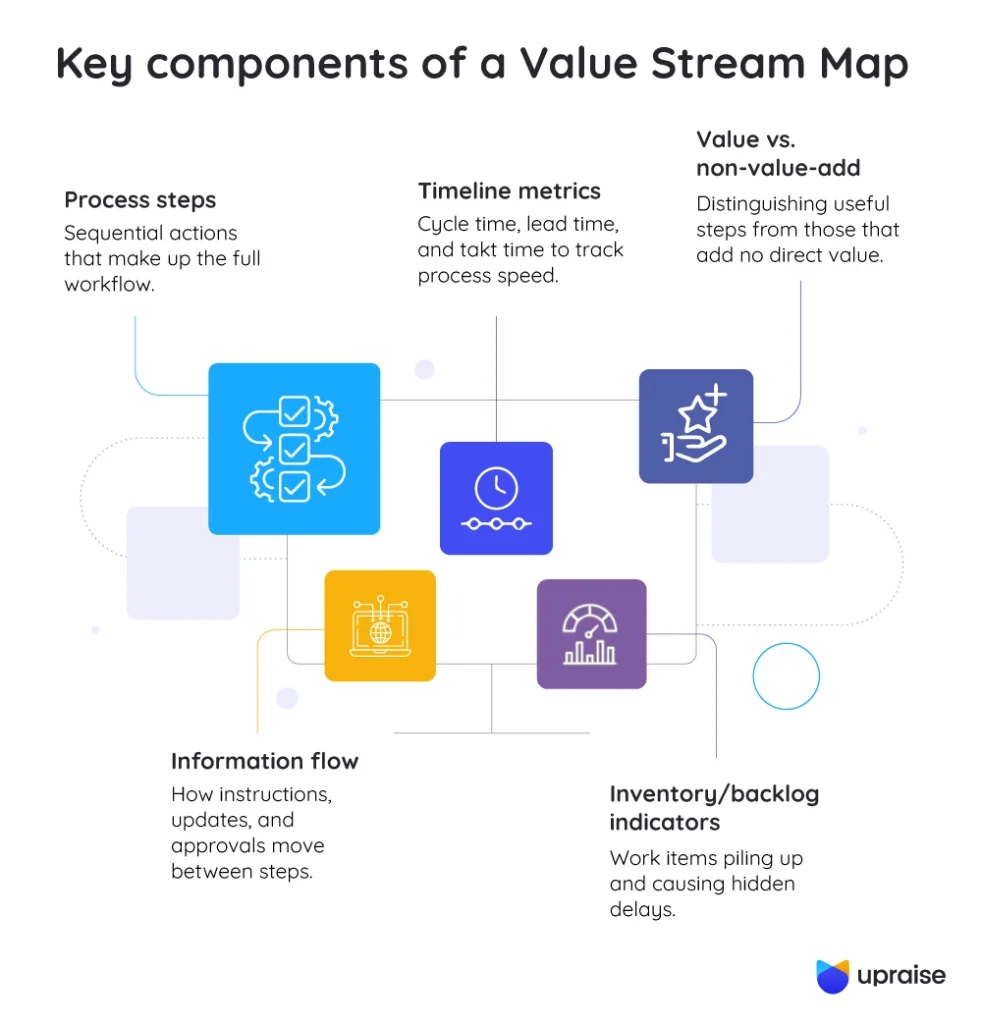

Key components of a Value Stream Map

When done right, a Value Stream Map uncovers the visible steps as well as the delays, dependencies, and inefficiencies that typically go unnoticed.

Here are the core components that make up a typical Value Stream Map.

1. Process steps

These are the individual actions or phases that make up the full workflow. This could include stages like Job Requisition Created, Candidate Shortlisted, Offer Extended, and Employee Onboarded. Each step is laid out sequentially to show how work flows from start to finish.

2. Information flow

Alongside the physical flow of tasks, a Value Stream Map also tracks how information is shared. This includes emails, approvals, notifications, or system triggers; anything that passes instructions, decisions, or updates from one part of the process to another.

In a high-performing HRMS setup, this might involve integrated workflows that trigger actions based on status changes. But in many teams, some of these touchpoints still rely on informal handoffs or manual follow-ups. Using Value Stream Mapping techniques helps pinpoint where automation or better system integration could make a measurable impact.

3. Timeline metrics

These include key time-related data points:

- Cycle time: How long it takes to complete each individual step.

- Lead time: The total time from the beginning to the end of the process.

- Takt time: The word “takt” is derived from the German word “Taktzeit,” meaning “cycle time” or “rhythm”.It is the pace at which production needs to be completed to meet the demand. It is more commonly used in manufacturing processes than in HR. But it can still be valuable for HR processes during high-volume periods like mass onboarding to ensure that work is moving as fast as you need it to.

When mapped together, these metrics reveal where time is lost through delays and inefficiencies like batching work or waiting on dependencies.

4. Inventory or backlog indicators

In manufacturing, this refers to items piling up between steps. In HR, it’s more abstract but just as relevant. Think of resumes sitting in a queue, pending approvals in a system, or unfinished tasks on someone’s to-do list. These backlogs create hidden delays that aren’t always visible in performance metrics but directly affect throughput.

5. Value vs. non-value-add classification

One of the core purposes of a Value Stream Map is to distinguish between activities that create value for the end user (in this case, employees or stakeholders) and those that don’t. Activities that don’t add direct value may be necessary, but you can always improve how you go about them and make the processes more efficient.

For example:

- A welcome email sent automatically = value-adding.

- A form that has to be downloaded, signed, and re-uploaded = non-value-adding (and likely replaceable with e-signature integration).

By mapping your processes through this lens, it becomes easier to spot where modern Value Stream Mapping techniques like digital automation, standardization, or platform consolidation can eliminate unnecessary friction.

Steps to create a Value Stream Map

If you’re mapping a process for the first time, begin with one that feels unnecessarily complex or inconsistent. It may not be dysfunctional, but it probably involves more back-and-forth than it should, or relies on too many manual touchpoints.

Look for high-visibility workflows, like onboarding, payroll, or offboarding, where even small delays are felt across the organization. Starting here allows you to pull up meaningful insights quickly, without needing to overhaul your entire system at once.

Once you’ve chosen your process, here’s how to map it step by step.

Step 1. Walk through the process yourself

Before you map anything, spend time tracing the process from end to end. Start at the beginning, whether that’s a job offer, a leave request, or a payroll cycle, and follow it all the way through to completion. What triggers the process? Who touches it? What tools are involved? Where does it slow down?

It helps to walk through the process more than once. Follow it for two or three real cases, not hypotheticals. You’re not trying to create a policy document. You’re trying to see what’s really happening.

Step 2. Bring the right people into the room

You can’t map a process accurately if you’re only seeing it from your own seat. Bring in everyone who plays a role in the process, whether they’re moving the work forward or approving it from the sidelines. Sometimes the most revealing gaps surface when someone says, “Oh, I didn’t know you were waiting on me for that.” And finding and fixing that communication gap is gold.

This step matters more than most people realize. A Value Stream Map only works when it reflects lived reality, not just what’s written in your SOPs.

Step 3. Plot each step on a timeline

Now start laying out the steps. You don’t need fancy tools for this—sticky notes and a whiteboard often work better than spreadsheets in the early stages.

For each step, ask:

- What exactly happens here?

- Who does it?

- How long does it take, on average?

- What needs to happen before this can begin?

- Where does it go next?

Note down waiting periods and handoffs, too, and not just the actions. Waiting is part of the process, and is often where the biggest delays live.

Step 4. Layer in your metrics

Once the flow is mapped, it’s time to understand how it performs. Add in:

- Cycle time: Time to complete each individual step.

- Lead time: Total time from start to finish.

- Handoffs: Points where work moves between people or systems.

You don’t need perfect data here. Even rough estimates can reveal whether most of your delays are happening in approvals, system transitions, or between teams.

Step 5. Identify pain points and friction

Now take a step back. What feels slower than it should? Where are things piling up? Are there manual steps that create bottlenecks, like emailing spreadsheets, waiting on approvals, or entering the same data into two different systems?

Ask the people doing the work so that you also create a solid feedback loop with everyone involved. Often, the fix isn’t major. It’s just something no one had the full visibility to notice before.

Step 6. Draw the future

Once the current-state map is done, use it to imagine a better version. If a form is causing frequent delays, flag it for redesign. If a task can be consolidated into a single system, document the change. If certain approvals can be automated, note it and consider how your existing value stream management software can help you with it. Consider tools that centralize approvals, records, and org structures within your existing workflow stack.

Your future-state map doesn’t need to be perfect. It just needs to be clearer, cleaner, and more intentional than what you have now. It’s the first draft of a better system and the baseline for your next round of improvements.

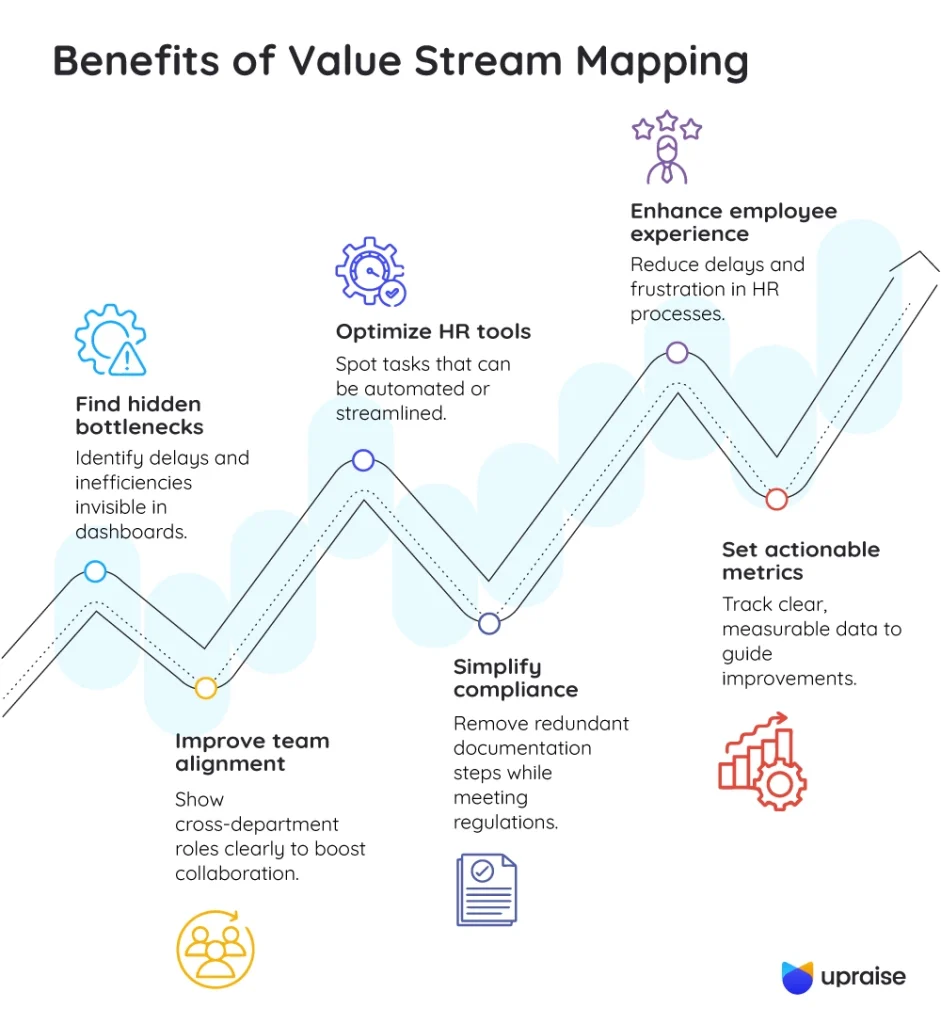

Benefits of Value Stream Mapping

Here are some of the most important benefits of creating a Value Stream Map.

- Find hidden bottlenecks: Mapping each step reveals delays, like approvals sitting in inboxes, manual data entries, or duplicate tasks across teams, that aren’t always visible in dashboards.

- Improve team alignment: When HR workflows span departments like talent acquisition, IT, and payroll, VSM helps everyone see how their roles connect, reducing confusion and making collaboration easier.

- Make better use of your HR tools: VSM highlights manual tasks or unnecessary steps that could be automated or streamlined within the systems you already use, ensuring tools are aligned with workflows.

- Simplify compliance and record-keeping: By clearly mapping documentation steps, VSM makes it easier to spot and eliminate repetitive or unnecessary compliance tasks, simplifying processes while meeting regulations.

- Provide smoother employee experiences: Streamlined workflows mean fewer delays and less frustration for employees during onboarding, internal moves, payroll, or benefits management. All of this eventually adds up and impacts overall employee engagement and performance.

- Establish clear, actionable metrics: VSM provides concrete metrics, like task durations and frequency of delays, allowing HR teams to set realistic goals, measure improvements over time, and demonstrate progress to leadership.

When used consistently, Value Stream Mapping helps HR teams create processes that are not only faster and more reliable but also easier to maintain as the organization grows. That said, it’s just as easy to misuse the tool, and when that happens, the map can end up looking neat on paper but solving very little in practice.

Common mistakes in Value Stream Mapping

Like any tool, Value Stream Mapping is only as good as the way it’s applied. When rushed, oversimplified, or treated like a checklist, it can overlook the very problems it’s supposed to find. Here are some of the biggest mistakes HR teams make—and how to avoid them:

- Mapping the “ideal” process instead of the real one: It’s tempting to map how things are supposed to work, but real insight comes from mapping what actually happens, including the workarounds no one talks about.

- Leaving out the people who do the work: Managers and process owners see one side of the process. Coordinators, recruiters, and admins often see where things really get stuck. Without their input, your map will have gaps you can’t afford.

- Focusing on tools instead of flow: It’s easy to get caught up listing every system involved. But VSM isn’t about your software, it’s about how work and information actually move. Tools matter, but flow comes first.

- Treating VSM like a one-and-done exercise: Processes evolve, and your map must evolve with them. If you don’t revisit your map after big changes like process or technology updates, it stops reflecting reality and loses its value.

- Trying to fix everything at once: A full map reveals a lot of issues, but trying to tackle them all guarantees overwhelm. Start small, focus on the highest-impact changes, and build from there.

Steer clear of these common missteps, and you’re already halfway toward making better use of Value Stream Mapping—and the employee management tools you might not even realize you’re underutilizing.

Turn clunky processes into efficient functions with Value Stream Mapping

By now, we’ve seen how Value Stream Mapping helps make sense of complex HR workflows by making the invisible visible. It gives you a clear view of what’s slowing things down, where manual work is creeping in, and how well your current systems are actually supporting the people using them.

But clarity alone isn’t enough. Once you’ve mapped out the current state, improvement depends on what you do next. That could mean simplifying handoffs, removing redundant steps, or rethinking how performance is tracked and supported with the right tools.

Next, connect your future-state map to clear owners, SLAs, and automation, using your existing tools to operationalize changes. Bring goal setting (OKRs), continuous feedback, and performance reviews directly into your daily workflow.

If you’re ready to act on your VSM insights, pilot one improved workflow, measure lead/cycle time changes, then scale incrementally.

FAQs

1. What are the key benefits of Value Stream Mapping in improving processes?

Value Stream Mapping shows you exactly where delays happen, which steps are creating value, and where time and effort are being wasted. For HR teams, this means fewer bottlenecks, better coordination across teams, and a clearer path from insight to action.

2. How do you use Value Stream Mapping in a lean manufacturing process?

In lean manufacturing, VSM is used to map the flow of materials and information across every stage of production. You identify each step, measure how long it takes, and assess whether it adds real value. The goal is to streamline the flow and reduce waste, whether that’s downtime, excess inventory, or inefficient communication.

3. What are the steps involved in creating a Value Stream Map?

Start by choosing a specific process to map. Walk through every step with the people who are directly involved—what happens, who’s responsible, how long it takes, and where delays show up. Capture both the actions and the waiting periods. Once you’ve mapped the current state, you can start designing a cleaner, more efficient future map.

4. How can Value Stream Mapping help identify bottlenecks in production?

VSM gives you a way to track where work is slowing down. Bottlenecks often hide in the gaps between teams, systems, or approvals. Mapping the process helps you spot long wait times, redundant steps, or overloaded handoffs that are causing hidden delays.